Quality

Quality

Safety

Safety

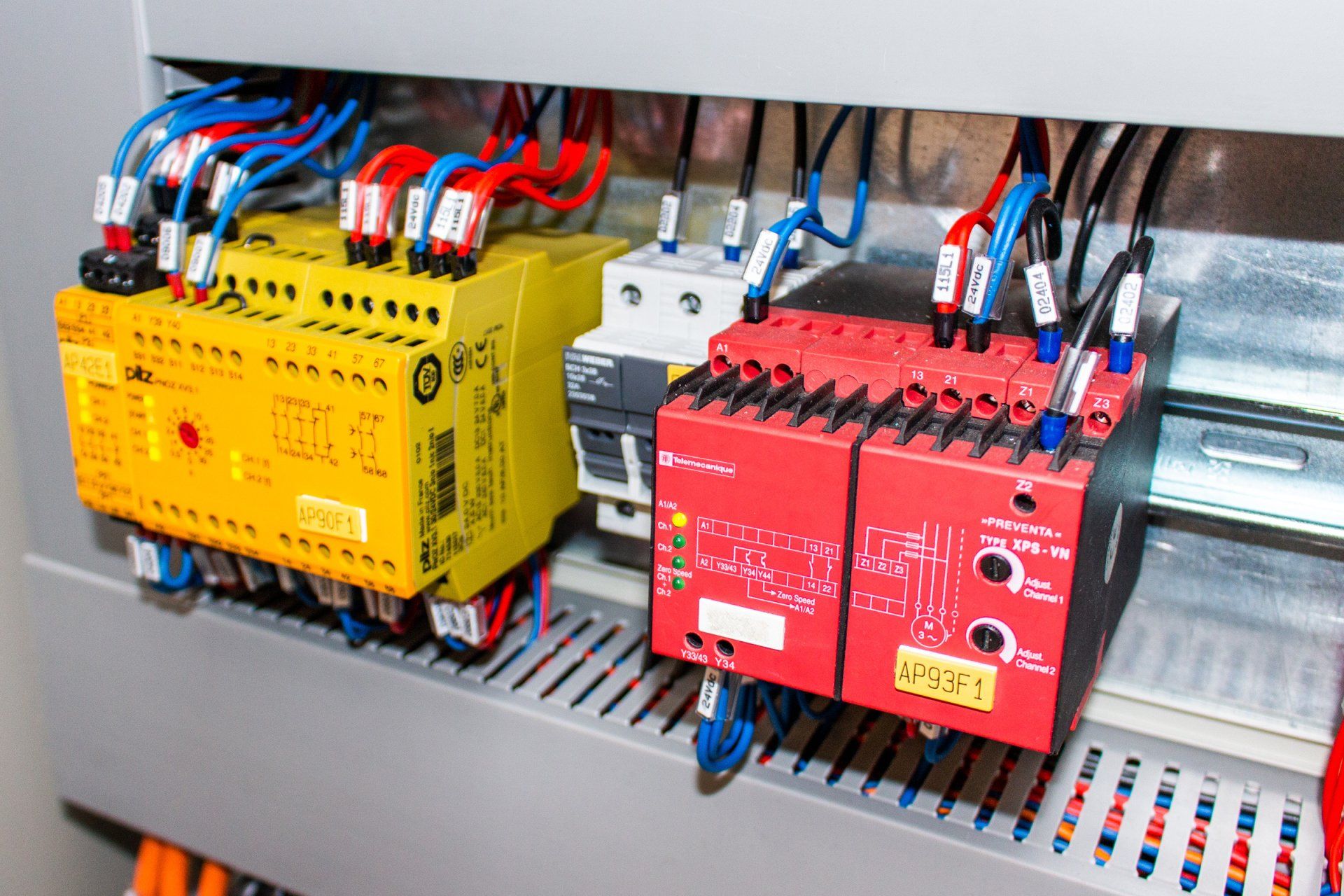

BETA machines are compliant with all European Standards about safety of machinery and include all the most updated design principles about the safety of machines. About the safety systems, three redundant modules are used with the highest safety level available on the market: one for emergencies, one for interlocked safety guards, and one for zero speed detection (which allows to unlock and open the doors only when the machine is completely at standstill).

All dangerous zones (main rolls, scroll spreader rollers, transmission, liftable trough, batcher) are properly protected with different systems depending on risk type and access frequency: there are fixed lids and interlocked sliding guards with electromagnetic door locking or RFID switches.

The control systems that manage the safety-related parts (SRP/CS) of this machine (emergencies and interlocked safety guards) use high-quality and well-tried components, and are classified in

Cat. 3 with PL d

(according to ISO 13849-1). The control systems and all related safety parts are designed so that a single fault in any of these parts does not lead to the loss of the safety function and, whenever reasonably practicable, the single fault is detected: when a single fault occurs, the safety function is always performed.

3D CAD

& FEA analysis

3D CAD

& FEA analysis

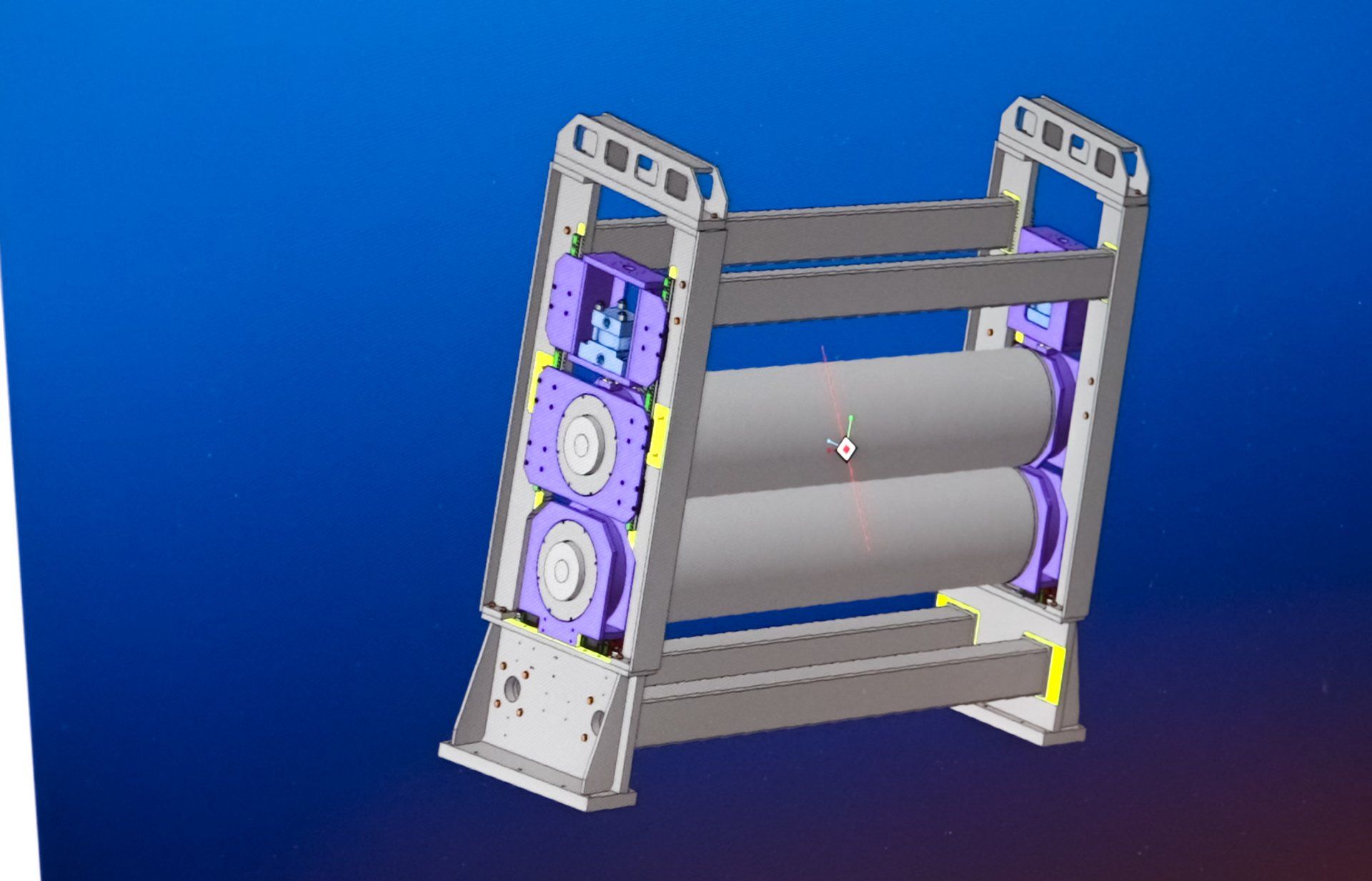

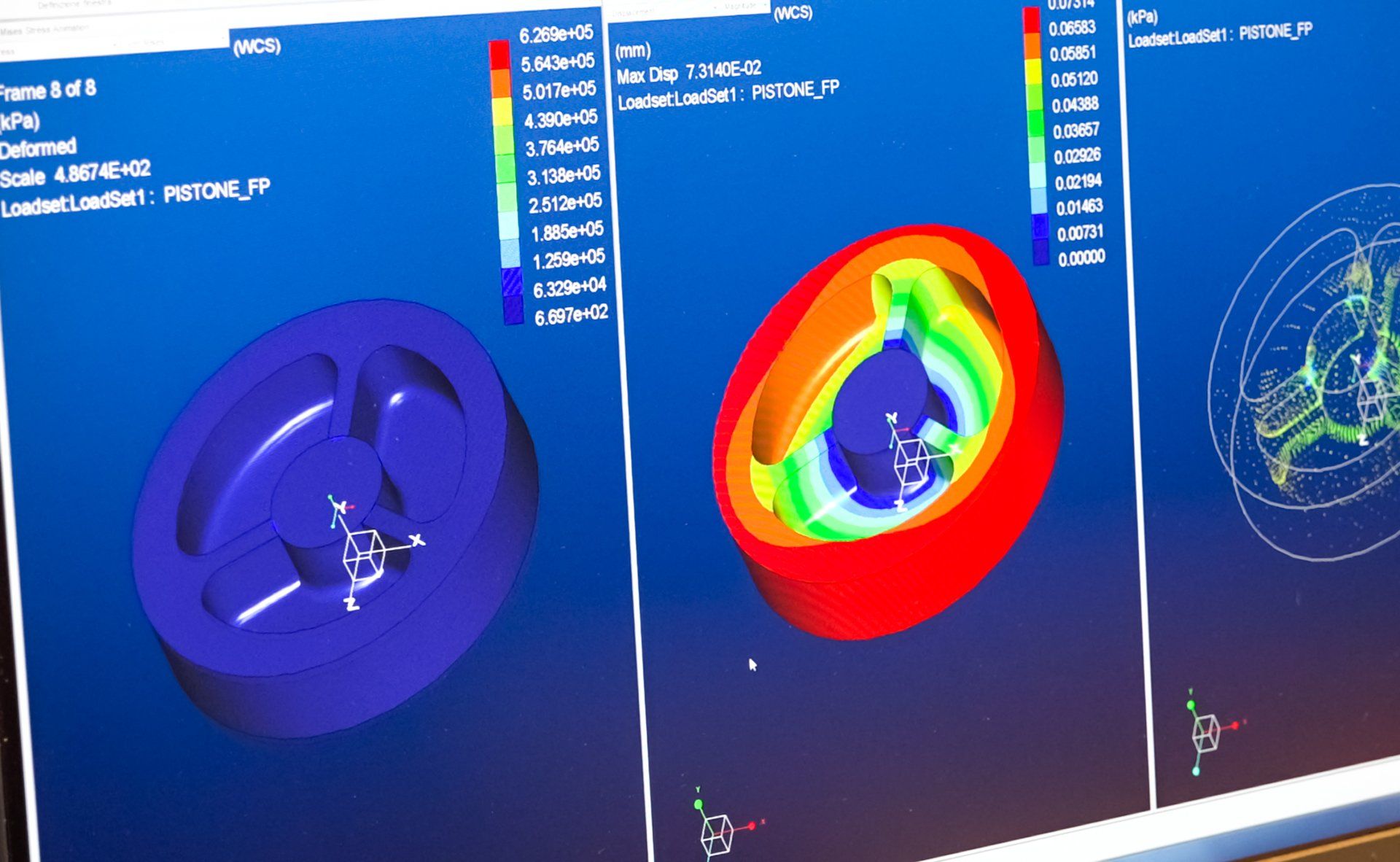

BETA design department makes use of a 3D CAD with FEA analysis modules, and is able to guarantee our Customers the highest quality and reliability of every component of our machines.

The FEA analyses allow the verification or every design detail of our machines simulating stresses, pressure, and temperature.

Marking and traceability

Marking and traceability

Each part of every new Beta-Roll® is marked with a micro-percussion marking device, ensuring a complete traceability of the Beta-Roll® and of all of its components.

This ensures our Customers the possibility of tracking the whole history of every Beta-Roll®. Only the original Beta-Rolls® are marked with Beta Machinery logo, a unique serial number, and a coded tag, assuring the highest transparency of the supply.