Equipressure Padder

Equipressure Padder

Features

Features

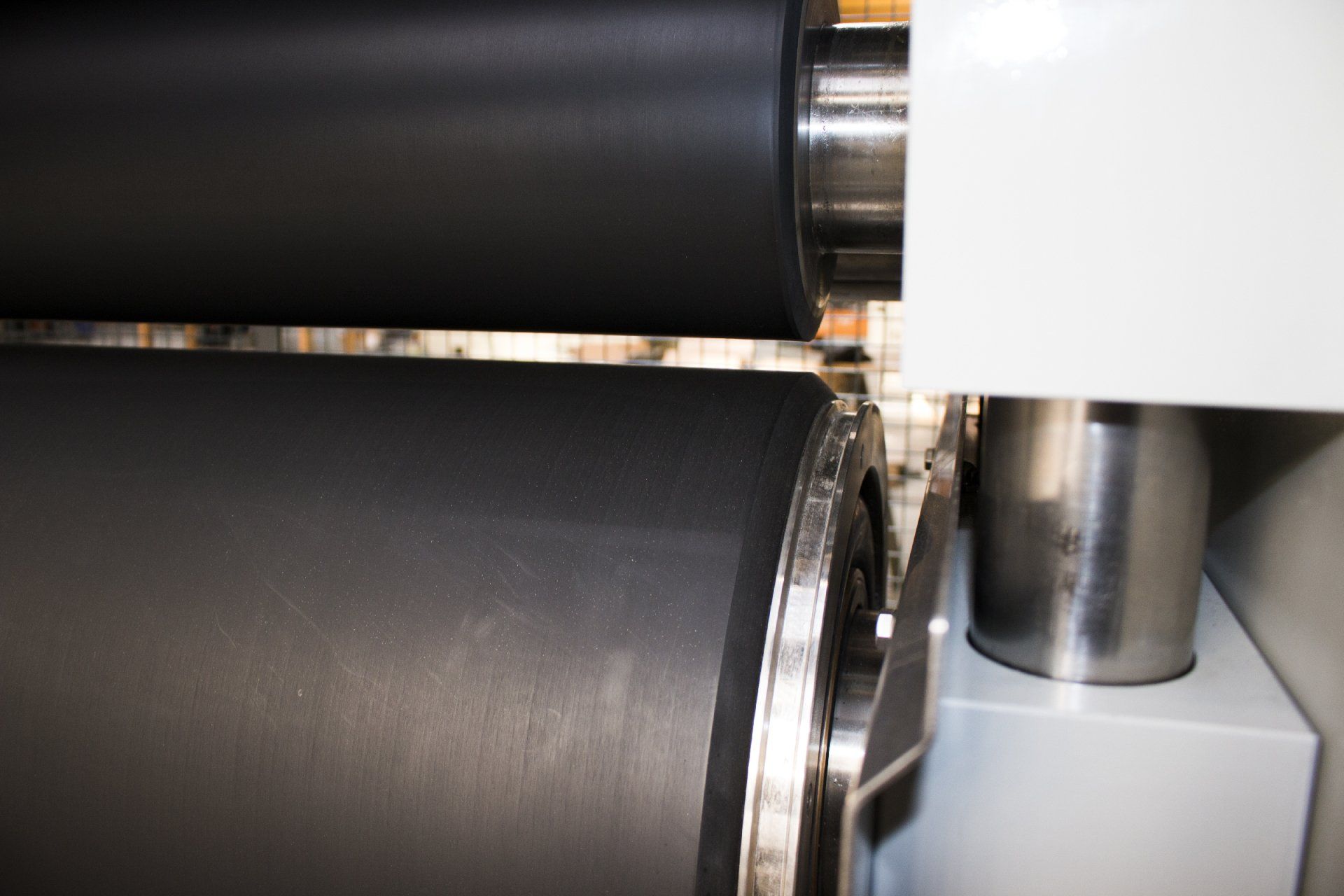

All BETA Padders are equipped with equipressure Beta-Rolls® (working pressure up to 120 N /mm), with table width up to 6.000 mm and with an onboard 20-bar air compressor for the pressure system of the machine, all the machines can be supplied with stainless steel frame.

- Zero deflection of the rolls at any working pressure

- High squeezing efficiency (100 N/mm)

- High squeezing load (up to 36 ton)

- Tablewidth up to 6.500 mm

- Speed up to 300m/min

- Low operational costs

- Great accessibility for maintenance, roll disassembling, cleaning, and threading

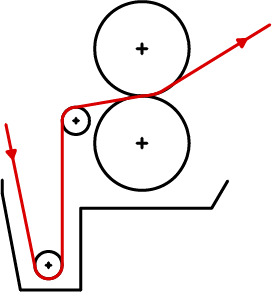

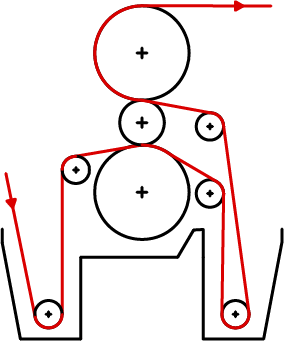

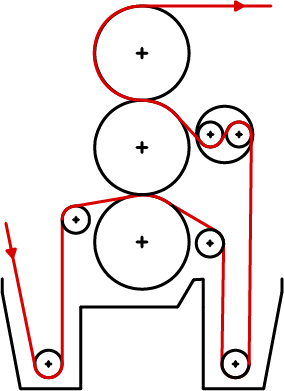

Layout

Layout

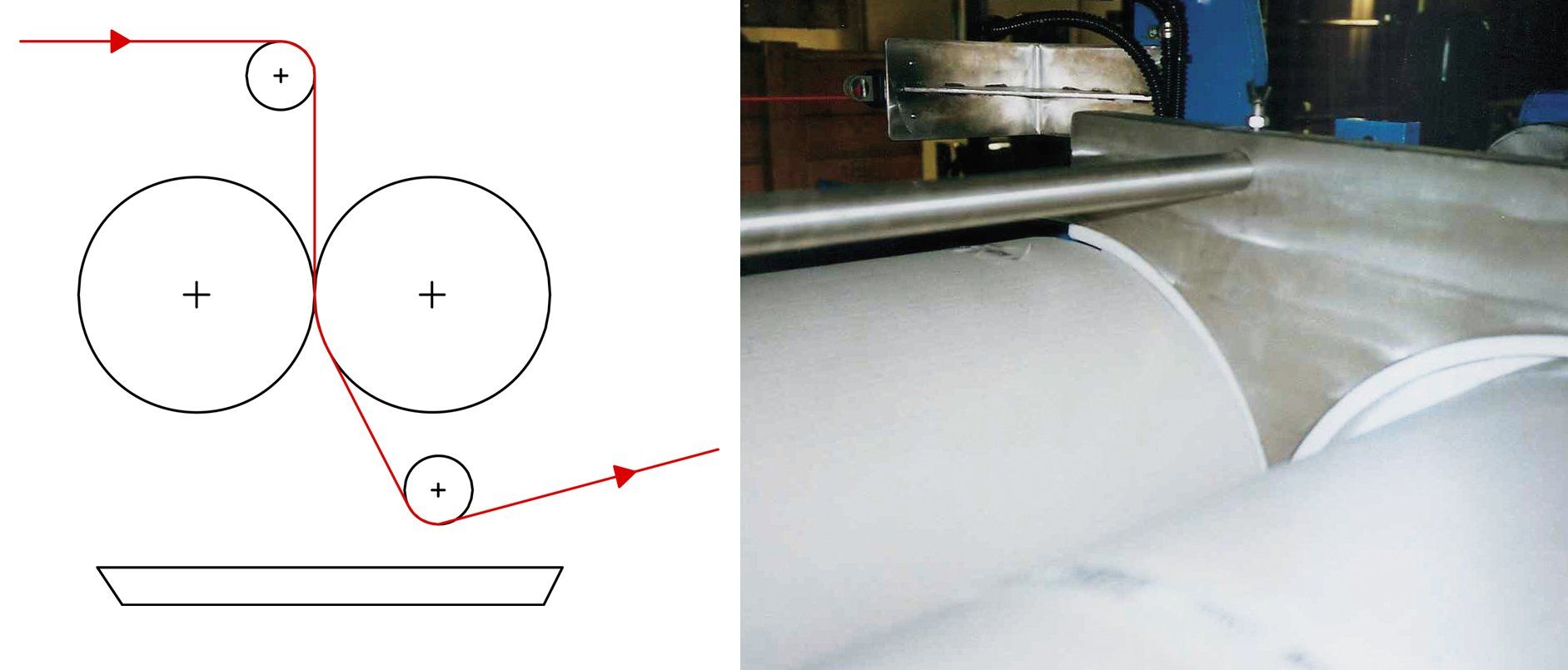

- Microengraved steel roll

- Stainless steel trough

- Micrometric thickness regulation

- Two foam distribution heads, for single of double side impregnation of the web

- OPTIONAL: circulation of cooling liquid in the rolls

Impregnation groups

Impregnation groups

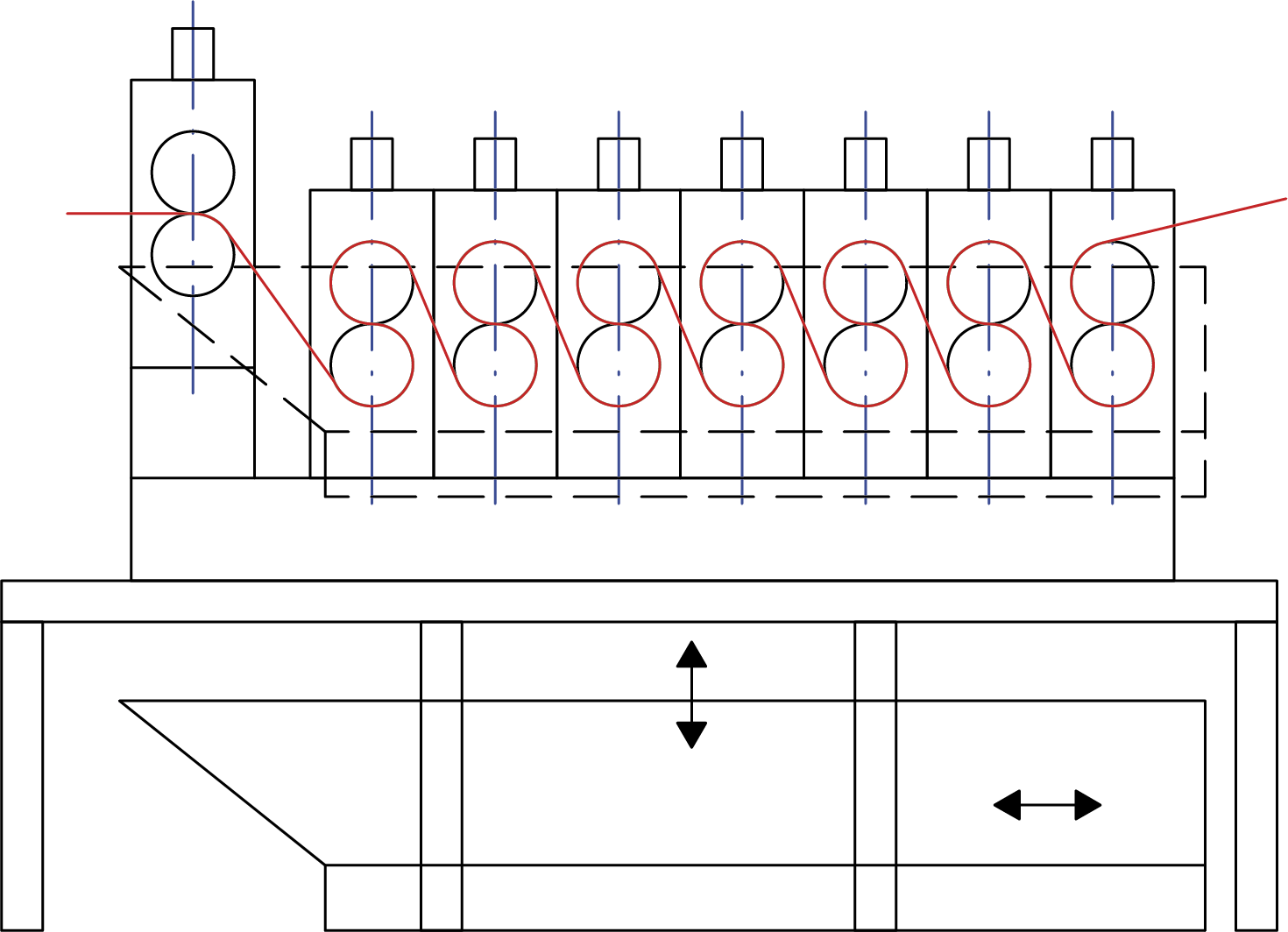

Multiple impregnation groups can be designed according to the technical requirements of the Customer.

Micrometric thickness regulation can be independently set for each impregnation group and on each side of the rolls.

Movable and liftable stainless steel troughs can be included to offer turnkey plants.